Glass and hose are widely used in cosmetic packing material. We introduced it in Knowledge of inner packing material of cosmetics——Glass and Knowledge of inner packing material of cosmetics ——Hose. This chapter introduces and analyzes the final cosmetic packing material—plastic.

Plastic

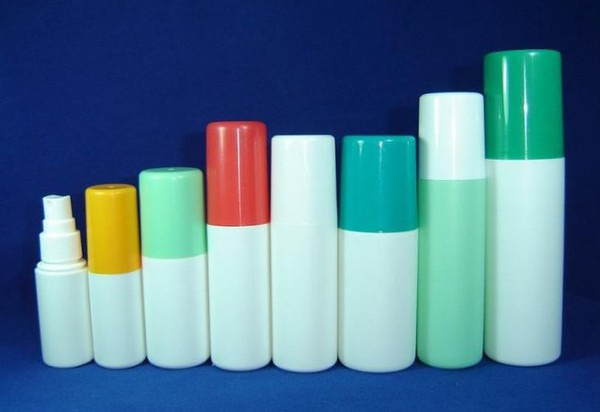

1. Plastic bottle is usually PP, PE, K material, AS, ABS, acryl and PET.

1. Plastic bottle is usually PP, PE, K material, AS, ABS, acryl and PET.

2. Cream bottle with thick wall, bottle cap, bottle plug, gasket, pump head and dust cover are injection molding. PET blown bottle is formed with two steps, tube embryo is injection molding, and blown bottle is used to pack finished product. Emulsion bottle and washing bottle with thin walls are blown bottles.

3. PET material is an environmental material which features high barrier property, light weight, no crushing, chemical resistance and strong transparency. It can be made to nacreous, colored, magnetic white and transparent. It is widely applied in hair gel packing. Bottleneck is usually standard calibers 16#, 18#, 22# and 24#. It can be used by equipping pump head.

4. Injection molding bottle is made with acryl. Its chemical resistance is relatively weak. Generally, it cannot directly pack the paste, and it needs to be equipped with liner for insulation. It should not filled too full so as to prevent paste from entering between liner and acryl and avoid crazing. The packing during transportation is relatively high. After being scratched, the scratch will be very significant. With high permeability, its wall looks thick, and the price is high.

5. AS and ABS: AS transparency is better than ABS, and its tenacity is good.

6. Mold development expense: The price for mold of blown bottle is between RMB 1,500—4,000 and the price for injection mold is between RMB 8,000—20,000. The cost of using stainless steel for mold is higher than alloy material, but it is durable. Several molds can be made for one time. It depends on production demand. If the production demand is big, 1 for 4 or 1 for 6 molds can be selected. It is decided by customers.

7. The order quantity is usually 3,000—10,000. The colors can be selected. It is usually focused on frosting with primary color and magnetic white or pearl powder effect. Although the bottle and the cap are provided with the same color concentrate, their materials are sometimes different, and they have color difference.

8. Silk print contains common ink and UV ink. UV ink has a better effect with a sense of luster and dimension. During production, plating should be made first for color confirmation. The silk print effects for different materials will be different.

9. Processing process (such as gold blocking and silver blocking), gold powder and silver powder have different effects. Hard material and smooth surface can adopt gold blocking and silver blocking. The blocking effect on the soft surface is not good, and it easily falls off. The luster of gold and silver blocking is better than gold and silver printing.

10. Bottle cap is usually equipped with inner gasket, pull cap and inner plug. Some are equipped with a spoon or a dropper. It is done for the sake of its sealing property and use convenience.

11. The product period is proper and about 15 days. For silk print, cylindrical bottle can be calculated as a single color, while flat or special shaped bottle is calculated as bi-color or multiple colors. The silk print board expense or fixture expense for the first time will be paid. The unit price for silk print is RMB 0.08/color-RMB 0.1/color, the unit price for screen printing plate is RMB 100—200/item, and the unit price for fixture is about RMB50/piece.

(1) Cream bottle + outer cap (production machine: injection molding machine)

Injection molding cream bottle is made with PP and PETG materials (they are new materials with good transparency. Liner is not needed, and double-layer bottle is available if cost is saved.), acryl (it has good transparency. Liner is usually required. Paste cannot be used directly, or the bottle body will crack.) and ABS material (it is used in electroplating accessories and can be colored easily.). The cap is usually made with PP material, inner cap PP + outer cover acryl, electroplating outer cap, alumite outer cap or oil injection cap.

Production process:

Bottle body: PP and ABS bottles use solid colors. PETG material and acryl bottle use transparent color with clear transparency. Acryl bottle wall is sprayed with colors, which can reflect the light and has a good effect.

Printing: Bottle body can be treated with silk print, gold blocking and silver blocking. The inner cap of double-layered cap can be treated with silk print. Outer cap has a transparency effect. The outer cap uses alumite which can be embossed with a logo.

(2) Vacuum bottle + outer cover of pump head (liquor essence bottle, toner bottle and emulsion bottle) and injection molding vacuum bottle are made with AS material. It can directly touch the paste without suction tube and with vacuum design + pump head (electroplating) outer cover (transparent and solid color).

Production process: Vacuum bottle is transparent and multipurpose, and solid color is seldom used.

Printing: Bottle body can be treated with silk print, gold blocking and silver blocking.

(3) Blown bottle (liquor essence bottle, emulsion bottle or toner bottle) (production machine: blowing machine)

A. Process of blown bottle

In terms of plastic material, it is divided into PE blown bottle (it is relatively soft, uses solid color and forms in one time.), PP blown bottle (it is relatively hard, uses solid color and forms in one time.), PET blown bottle (it is highly transparent. It is mostly used in toner and hair gel. It is an environmental material and forms in two times.), and PETG blown bottle (its transparency is better than PET, but it is not frequently used in China. Its cost and internal scrap produced are high. It forms in one time and there are few unrecyclable materials.)

Combination forms: Blown bottle + inner plug (PP and PE materials are commonly used.) + outer cover (PP, ABS and acryl are commonly used. It also adopts electroplating and alumite. Oil injection toner is commonly used.) or outer cover of pump head (liquor essence and emulsion are commonly used.) + press cap + lifting cover (lifting cover and press cap are mostly used in daily chemical line with great circulation.).

B. Production process of blown bottle

Bottle body: PP and PE bottles use solid colors. PETG, PET and PVC materials are transparent and feature colored transparency and clear transparency. Solid color is seldom used. PET bottle can also be sprayed with colors.

Print: Silk print, gold block and silver block.

(4) Pump head

1. Distributor is divided into tying type and screwing type. In terms of function, it is also divided into mist spray, foundation cream, emulsion pump, gas spray valve and vacuum bottle.

2. The size of pump head is determined by the caliber of bottle body. The specification of mist spray is between 12.5mm--24mm, and the water yield is between 0.1ml/time --0.2ml/time. It is generally used on the package of perfume and hair gel. If the pump calibers are the same, the tube connecting length can be determined by the height of bottle body.

3. The specification of emulsion pump is between 16ml--38ml, and the water yield is between 0.28ml/time --3.1ml/time. It is generally used in cream and washing products.

4. Vacuum bottle is usually in a cylindrical shape. Its specification is 15ml--50ml or 100ml. Its overall volume is relative small. Thanks to the atmospheric principle, it can prevent contamination when cosmetic is used. Vacuum bottle is made with alumite, plastic electroplating and colored plastic. Its price is higher than that of other common containers. The requirement of common order quantity is not high.

5. PP material is usually used (production machine: injection molding machine). The outer ring is an alumite sheath which is treated with electroplating process, gold blocking and silver blocking.

(1) In terms of bottle body function:

A. Pump head of vacuum bottle without suction tube + outer cover

B. Pump head of common bottle with suction tube + outer cover or no outer cover

(2) In terms of pump head function:

A. Pump head of emulsion (applicable to emulsion contents, such as emulsion, bath cream and shampoo)

B. Pump head of mist spray (applicable to water-based contents, such as mist spray and toner)

3. In terms of appearance:

A. With cover pump head, the outer cover has a protection function. (It is used in the product with a small volume of below 100ml.)

B. Without pump head, it has a special design and can be locked. The content will not be flowed out due to pressing. It has a protection function, is portable and can reduce the cost. (It is used in the product with a small volume of above 100ml.) The pump heads of bath cream and shampoo in daily chemical line are designed to contain no outer cover.

4. In terms of production process:

A. Electroplating pump head

B. Alumite pump head

C. Plastic pump head

(5) Outer cover

PP material is usually used. Sometimes, PS, ABC and acryl materials are used. (Production machine: injection molding machine)

In terms of structure, the double-layered cap is divided into:

A. PP inner cap +PS and acryl outer cover

B. PP inner cap + outer cove PP and ABS electroplating

C. PP inner cap + alumite outer cover

D. PP inner cap +PP or ABS oil injection outer cover

Single-layered cap: PP material is commonly used.

Process: The cap side can be treated with gold blocking, silver blocking and oil injection.

The inner cap of double-layered cap can be silk printed with a logo. Outer cap has a transparency effect. The outer cap uses alumite which can be embossed with a logo.

You might be puzzled at reading the above content. However, you do not need to be so professional about everything. Generally, cosmetic OEM manufacturers will provide professional personnel to explain it to you. For different materials, you need to learn about the following differences:

PET: PET is highly transparent. The bottle is soft and can be pinched to be concaved, but it is slightly harder than PP.

PP: PP bottle is slightly softer than PET. It is easily pinched, but its transparency is poorer than PET. Therefore, some non-transparent shampoo bottle is commonly used. (It is convenient to squeeze.)

PE: The bottle is basically not transparent, and it is not as smooth as PET.

Acryl: It is thick and hard. Acryl is looks like the glass the most.